The recently-completed set of experiments with LPPFusion’s FF-1 device, combined with discussions with colleagues at the International Center for Dense Magnetized Plasma (ICDMP) conference in Warsaw, have produced a greater understanding of the ways impurities are produced in our device and how to reduce them. LPPFusion’s research team has long identified heavy-metal impurities, produced by the erosion and vaporization of the metal electrodes, as the key obstacle to obtaining higher plasma densities and thus higher fusion energy yield. Experiments with tungsten electrodes have led to some reductions in impurities, but not enough. The new understanding of how the impurities are produced has helped to plan the next steps in getting rid of them.

First, experiments in early September with the preionization system showed that erosion of the anode near to the insulator, a major source of impurities, was still continuing. The preionization system applies a tiny current between the electrodes prior to the main current. The idea is to get into motion lots of electrons, which the small current strips off atoms in the gas, producing ions, and thus “pre-ionization.” Having more electrons means that the electrons move slower, carry less energy and thus do less damage to the anode—a kind of deliberately-induced electron traffic jam (without advice from Gov. Christie!).

But measurements between shots of these small, several-microamp currents showed changes in the relation between the amount of current (controlled by the power supply) and the resulting voltage on the anode (up to 1500 kV). We were able to greatly change this voltage vs current curve between shots just by purging the chamber with high-pressure nitrogen. (Fig.1) The only thing that could change with just gas blowing around was tiny tungsten dust particles. These tiny particles could act as lightning rods, providing an easier path for the current and making preionization asymmetrical. But if dust was continuously being produced (and it was, even after many purges) then vaporization of the tungsten to produce the dust was also occurring. Indeed, the dust particles, by concentrating the main, million-ampere current, made vaporization of the anode far easier. So, “dust breeds dust” and erosion was not going to stop until we had a fresh, smooth anode.

Next, when we disassembled the vacuum chamber at the end of September, we confirmed that oxidation contributed to the erosion of tungsten. The deposits on the tungsten were clearly a different material, not pure tungsten. (From the dark gray color, it is probably a compound of tungsten, oxygen and the fill gases, deuterium and nitrogen.) Tungsten oxide is about 200 times easier to vaporize than pure tungsten, and we found from a literature search that tungsten nitride is not that much better than the oxide. We could measure the optical absorption of the deposits on our windows and from this determine that the total mass of impurity metal in the plasma had indeed declined by about 60% from our previous experiments with copper electrodes. This was progress, but not enough.

More insight came when LPPFusion’s Chief Scientist participated in the ICDMP conference in Warsaw in mid-October. This is a small conference of those working with the plasma focus device. One presentation by Czech researcher Monika Vilemova showed that when tungsten melts, tiny pores of gas burst open as bubbles, sending droplets of metal into the plasma to be vaporized. (All manufactured tungsten is porous and our electrodes are about 5% porous by volume.) This indicated that even for pure tungsten, erosion only requires heating to the melting point, not to the boiling point.

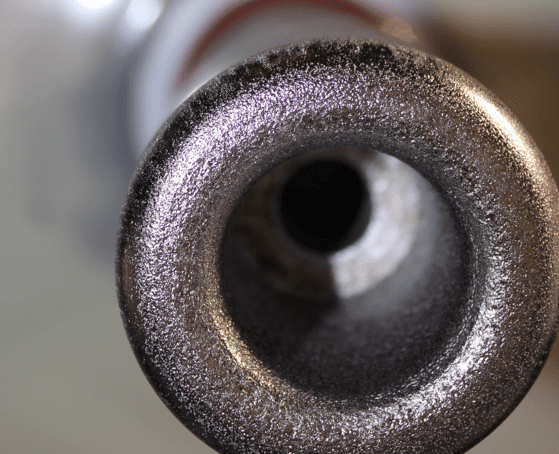

Other discussions pointed to a likely source of the electrodes’ second main region of erosion—the end of the anode. Previously, Lerner had blamed the anode’s heavy erosion on the electron beam that comes from the plasmoid. But when the anode was carefully measured during this disassembly, there was no evidence of the increase in erosion in the center of the anode that is expected from a beam. Perhaps, Lerner hypothesized, the erosion instead comes from high-energy particles leaking out of the plasmoid. But in Warsaw, Lerner saw anodes from the large PF-1000 plasma focus device that showed clear signs of erosion by the current filaments (dense vortices of current) prior to the formation of the plasmoid (Fig.2).

Figure 2. Erosion on anode tip of PF-1000 plasma focus device in Warsaw (left) shows evidence that it was generated by current filaments. Recombination radiation X-rays from tungsten impurities may have also caused erosion on FF-1 tungsten anode (right.)

A leading expert in plasma spectroscopy at the conference, Dr. Hans Kunze, suggested that with heavy metal impurities like tungsten, recombination and line radiation might be very important because they increase proportionally to z4, where z is the number of charges on the ion. In the case of tungsten, z can be as high as 74, depending on how many electrons the ion has lost. Recombination radiation occurs when electrons that have been stripped from an ion get back together with it, emitting UV or x-ray photons in the process. Line radiation occurs when the electrons that are still bound to an ion drop down to lower energy levels (like lower stair-steps) after being excited to higher ones.

For deuterium, which has only one electron, such radiation is unimportant once the plasma in the device heats up and all the electrons are moving freely. But Lerner calculated that with even a bit of tungsten impurity, the recombination and line radiation can be enough to melt tungsten and cause the heavy erosion seen at the anode tips. Thus impurity breeds more impurity. The erosion occurs only at the tips, since the intensity of the radiation also depends strongly on plasma density, which increases at the anode tip as the plasma is compressed inwards toward the anode axis. Since the plasma filaments touch the whole top surface of the anode, this radiation hypothesis explains why there was no central concentration of the erosion damage. Finally, this hypothesis would directly explain how impurities limit plasma density, as the energy loss from the radiation would prevent the plasma sheet from reaching high density.